When shopping for a solar PV system, you will likely encounter two types of solar cells, monocrystalline or polycrystalline. Manufacturers use crystalline silicon for both types of panels. This brief guide on the drawbacks and advantages could help your decision process.

Monocrystalline solar panels

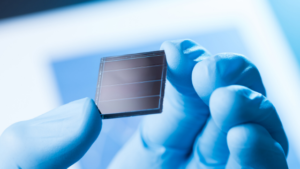

As the name suggests, monocrystalline solar panels use single silicon crystal for their composition. They are recognizable for their sleek dark black color and high-efficiency ratings. Manufacturers form silicon into bars or ingots to make monocrystalline cells.

Monocrystalline cells are far more efficient than polycrystalline cells. Since the cells only use a single crystal of silicon, they allow for more movement of electrons, generating a more significant flow of electricity. However, manufacturing monocrystalline cells costs more. This cost is passed along to the buyer. The process also creates more waste as the corners of each cell, once cut into a wafer, are shaved to create the typical cell shape.

If you have limited space on your roof, then monocrystalline panels would benefit you as the high efficiency will help maximize production. Monocrystalline panels are also likely to yield higher returns on solar investments when purchased.

Polycrystalline solar panels

Polycrystalline solar panels have an iconic blue color. Generally, they are less efficient than their monocrystalline counterparts. The most significant advantage of polycrystalline panels is a lower cost for both the buyer and manufacturer. However, their characteristic blue color and lower price make them more common in commercial solar projects rather than in homes.

Polycrystalline solar cells use several silicon fragments instead of a single crystal. Manufacturers melt the silicon and pour it into a mold to create a square. Once cooled, manufacturers cut the silicon into square wafer-shaped cells. The manufacturing process here is much more straightforward and clean, and there is no silicon waste. However, due to the presence of many silicon crystals in each cell, electrons have less space to move, thus lowering the efficiency ratings for polycrystalline panels.

Which is right for you?

At Everlight, we use sleek, jet-black panels designed to produce clean, renewable energy efficiently. Our panels come with licensed and expert installation and a team of experienced energy consultants monitoring your system after installation to ensure your energy output is working for you. Make the switch to solar and contact Everlight Solar for a free consultation today!